“I’m like a kid in a candy shop!” exclaims Brant Curtis, as we stand in the Wilbur Curtis Company warehouse factory in front of a ginormous metal machine.

The sweet treat in sight: a massive, thick sheet of stainless steel.

The task: bending that sheet of metal into the shape of a drip tray in under thirty seconds.

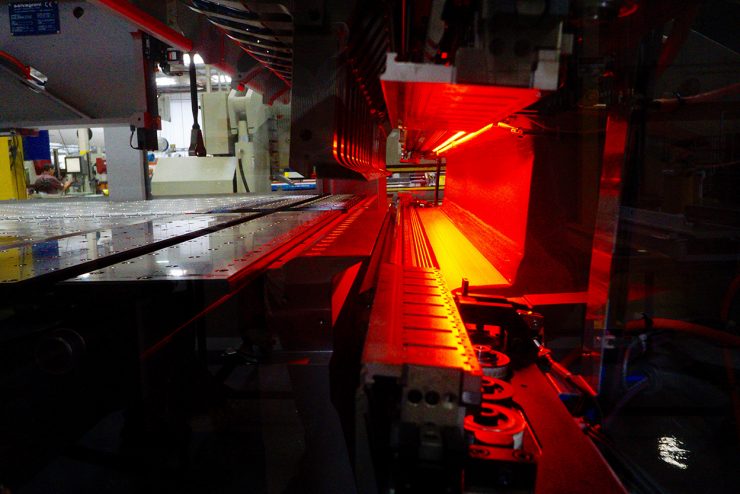

Curtis is the grandson of Wilbur Curtis, founder of the Wilbur Curtis Company, a family-owned American manufacturer of coffee brewing equipment. The younger Curtis works today as director of communications and innovation for the brand, which is headquartered in Montebello, California, southeast of Los Angeles. The excitement Curtis feels is the result of how effortlessly and quickly this robot is able to stamp the metal into shape. His excitement builds even more when we visit “The Laser,” as he simply calls it. It’s an industrial laser beam that cuts metal, sending sparks flying within a safe distance. This is how these products are made, in a process that allows our friends and partners at the Wilbur Curtis Company to produce nearly every element of their product line in-house, from raw steel to state of the art brewers.

The facility, the size of several airplane hangers, specializes in a wide array of brewed coffee makers—mainly drip coffee, for commercial use. While Curtis’s specialty coffee brewers only make up for 3% of the company’s revenue, it hasn’t stopped them from diving head first into the deep pools of the specialty coffee world. From crafting automatic pour-overs to creating their own Specialty Coffee Association of America campus for cupping and training, the family business is committed to contributing to the cutting edges of coffee culture.

Brant Curtis personally led my tour of the bustling, energy-efficient warehouse space. His dream is to transform this industrial warehouse south of LA into a destination for coffee enthusiasts—and it’s a dream gaining steam, from hosting events like Barista Nation and regional latte art throwdowns to offering up the space’s state-of-the-art lab for coffee certification.

One of the main rooms inside Wilbur Curtis Company is its sparkly showroom, literally. Meaning, the room sparkles with a variety of stainless steel coffee makers that the company ships to businesses around the world. The display pieces range in use, from early cappuccino machines of the ‘90s to bulk tea containers, custom-built drip coffee makers for Japanese convenience marts, and automatic pour-overs for high-end cafes.

Another important room in the Wilbur Curtis factory is, of course, the warehouse itself, Brant Curtis’s “candy store.” With a 48-hour turnaround on ordered products, each piece in the factory is made within hours of its order date. Every piece gets tested. Every prototype in the making gets a trip to the “Death Lab,” an area in which brewers brew for hours until their point of failure. Wilbur Curtis meticulously tests and re-tests their products to ensure that the best product is sent out to a customer.

The last main highlight of Wilbur Curtis Company is their brand spanking new training facility, the Curtis Training Lab. A one-year project, the room exists as a space for customers and for the specialty coffee world beyond.

“We used to have customers come in… they’d travel from all over the world and we used to taste coffee there in the warehouse,” Curtis explains. “And it’s like, guys… this is not… we can do better than this, come on! And so we built this in an effort to do that.”

The lab has a cafe-meets-kitchen-meets-laboratory kind of feel. The clean, white walls of plaster and tile are confronted by a playful “Coffee, please!” neon sign. The spotless countertops are covered with coffee “toys”–a La Marzocco Linea Mini, a La Marzocco Linea PB, Chemexes, their automatic pour-overs with built-in drip trays, you name it. Extra features include a microscope connected to a TV for close-up demos, curtains made for darkening the room, and red lights that remove the sense of sight for cuppers to properly taste test coffees.

Additionally, the lab is 95% SCAA certified. Wilbur Curtis’s idea to make the training lab an SCAA campus stems from a recent change from the SCAA itself. While the group initially hosted its own labs and taught certified classes, their recent move into office spaces prompted them to request its members to teach classes outside of industry events. In addition to their lab-required red lights (part of the sensory evaluation), Wilbur Curtis has posters, literature, documents, and lighting that align with the SCAA guidelines for training labs. While the room acts as a space for SCAA classes and customers, it’s also a place for customers to bring their customers and taste test coffees.

Hosting your own tasting at the lab is completely free.

“For us, this wasn’t built so that we could make money,” Curtis tells me. “This isn’t a profit center. We want to reach out to the industry and ultimately, we want people to see what we do. A lot of people don’t know that we manufacture this in Los Angeles, which is insane.”

For the greater good of coffee and coffee culture, Wilbur Curtis makes an effort to help create a delicious cup of coffee for all kinds of coffee lovers. Whether it’s the brand’s cutting-edge Seraphim batch brew system, or the coffee setup at the 7-Eleven across town, these products get made here, in Brant Curtis’s 21st-century candy store. A happy 75 years to ‘em and here’s to many more.

Wilbur Curtis is located at 6913 Acco Street, Montebello, California. Visit their official website and follow them on Facebook, Twitter, and Instagram.

Katrina Yentch is a freelance journalist based in Los Angeles. Read more Katrina Yentch on Sprudge.

The post Let’s Visit A Factory: The Wilbur Curtis Company of Montebello, California appeared first on Sprudge.